Technology

The Company has developed technology for the pumping of groundwater from areas of high groundwater salinity with this groundwater fed through a series of condenser ponds with gradually increasing brine content and then to crystalliser ponds in polyhouses from which very high quality salt is harvested. Salt purity is close to pharmaceutical and food quality. After harvesting, the salt is refined and packed for commercial sale.

A major problem facing the environment and the Australian agricultural industry is salinity. There is an acceptance by both government departments and the industry sector that the developed technology will play an important role in combating salinity in the Murray Darling Basin.

Solar power evaporation

Salt piles

Evaporation tunnels

The Facility

The established operation is located 12km west of the township Pyramid Hill in Northern Victoria. The facility is sited on 128Ha of land owned by the company. Within this facility an office, laboratory and warehousing is established.

The facility incorporates:

Pumping System

At the site 12 bores have been developed with a delivery capacity of 1.5 mega litres per day. The water from these bores is pumped directly into the evaporation system. A further pumping site, partially funded by the Victorian Government ‘Water for Growth Initiative’, consists of 10 bores with a delivery capacity of 1.3 mega litres per day and is established 3.5km to the west of the site. The water from this bore field is transported by means of a pipeline to the evaporation system.

Evaporation Pond System

The evaporation system is a series of ponds where the saline water from the bores is pumped into an initial pond. Due to solar evaporation, the salt density is increased. When salt density reaches certain levels the brine is transferred to the next pond ultimately ending in the crystaliser pond where salt crystals are formed.

The evaporation system consists of the following solar ponds:

Polythene-lined

- 15 x 1Ha Concentrator Ponds

- 1 x 1 Ha Crystalliser Pond

Non – Lined

- 7 x 1Ha Concentrator Ponds

- 1 x 1 Ha Crystalliser Pond

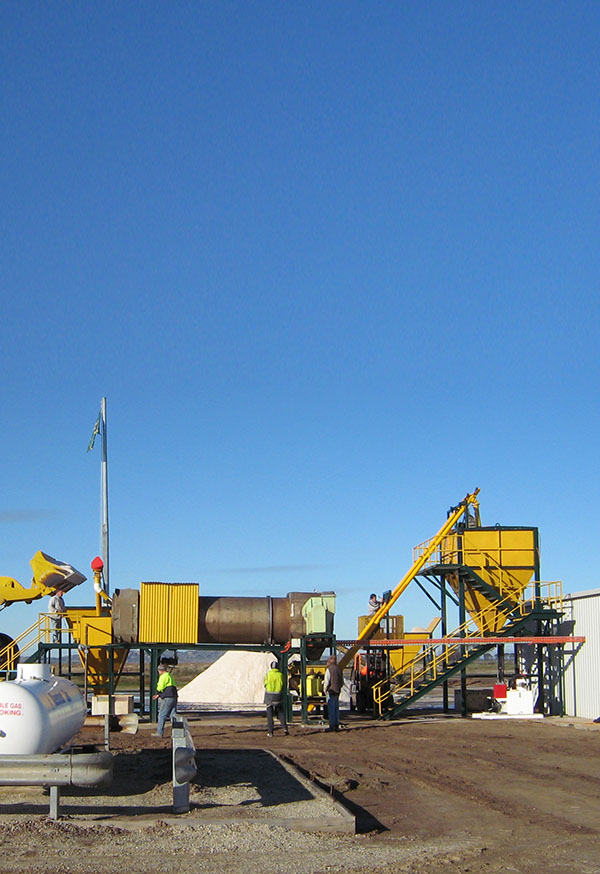

Salt Processing Facility

Equipment has been installed and is operational for the washing, drying, screening and bagging of salt.

Salt Refining

12 poly- houses (70mx12m) have been constructed specifically to produce a high quality of salt for the food industry. For the production of speciality gourmet flake salt, 15 purpose built machines have been installed.

Solar Pond

The 3000 square metre solar pond is integrated into the pond evaporation system. The pond has heat exchangers installed and is used for delivering a continuous 60 KW energy load in the form of heat to the flake salt drying process.

Address:

1142 Boort-Pyramid Rd

Pyramid Hill VIC 3575

Phone

03 5455 1299